Wood Doesn't Rust

Wood Doesn't Rust

- All building materials used for the structure of houses in New Zealand are required to have a minimum service life of 50 years to comply with the building code.

- Wood, used appropriately in accordance with building standards, will usually far exceed this.

- The mutual enemy of both wood and steel is moisture. Ingress of moisture into wall cavities should be minimised and the design should ensure that any moisture that does enter from leaks or condensation can drain and dry.

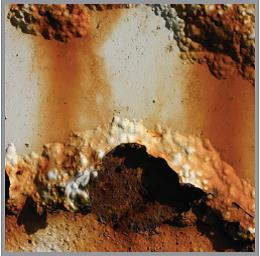

- Although steel is normally galvanised to protect it from corrosion, steel frames are susceptible to rust where the surface coating is cut, scratched or penetrated, and from edges that have been cut.

- Wood treated with the appropriate level of preservative, and properly maintained, can last in service for a hundred years or more.

Snug And Sound

- Wood is 400 times better as a thermal insulator than steel and 14 times better than concrete.

- Solid wood also has significant thermal mass properties, retaining heat from the day and releasing it at night.

- A steel framed wall will have an overall R-value of only 46-70% of a similar wood framed wall with the same amount of cavity insulation. R-value is the measure of the total thermal resistance of a building element to heat-flow when the internal and external environments are constant.

- A thermal break is needed when using steel to improve insulation and avoid the build-up of moisture from condensation that can lead to mould.

Wood Framing Is Fast And Adaptable

- Timber provides for flexibility of design, and allows modifications and tweaks to layout during the construction process - with steel framing this is more difficult.

- Builders are familiar with using wood, and usually prefer it. Advantages of timber reported by builders include ease of construction and quick erection times for timber frames and roofs.

- Cladding cannot be nailed onto steel frames - it has to be screwed on, unlike wood frames where cladding can easily be nailed.

- It's much more difficult to move support fixings for vanities, showers and kitchens in a steel framed house than it is in a wood framed house.

Wood Can Take The Heat

Wood Can Take The Heat

- Average building fires reach 700°C to 1000°C.

- Steel weakens as its temperature climbs above 230°C, retaining only 10% of its strength at 750°C.

- Wood does not ignite until it reaches over 250°C. Once it catches fire, wood develops a protective insulating char layer.

- Large timber beams have better fire resistance than unprotected steel beams of similar size because the interior of the timber remains much cooler.

- While wood can move a little with moisture, steel moves 2 - 3 times as much as wood with temperature.

- (There is no such thing as a "fireproof" building. The contents of most buildings are combustable - and it is contents rather than the structural components which pose the greatest fire hazard to life and property.)

No Shocks Or Surprises

No Shocks Or Surprises

- Wood, when dry, is a natural electrical insulator and will not conduct current or become live.

- Steel is a good electrical conductor and a steel frame is able to conduct a current is in contact with a live electrical source.

Safer Choice Of Timber Treatments

Safer Choice Of Timber Treatments

- Modern timber treatments balance the risk of decay against the desire to use as few chemical preservatives as possible, depending on the application.

- Boron is a relatively inert and benign compound. It is recognised by environmentalists to have been used successfully and without ill-effect in the New Zealand preservation industry for many years.

Wood: The Most Renewable Of All Building Materials

Wood: The Most Renewable Of All Building Materials

- Growth and production of one tonne of wood abosrbs a net 1.7 tonnes of CO2 from the atmosphere*.

- Production of one tonne of steel emits 1.2 tonnes of CO2 into the atmosphere.

- A typical steel frame emits 4.5 tonnes of CO2 into the atmosphere.

- A typical wooden house frame absorbs 9.5 tonnes of CO2 from the atmosphere.

(* Based on the anount of carbon stored in timber - making allowance for all the energy used and CO2 produced in its growth, haresting and processing.)

Timber Frames Mean Years Of CO2 "In The Bank"

Timber Frames Mean Years Of CO2 "In The Bank"

- Ongoing energy usage for a well built, properly insulated home will be similar whether built with a steel or wooden frame (although steel frames will "leak" more heat than a wooden frame is not properly insulated).

- The choice of wood or steel makes the difference between starting with either a healthy CO2 credit or deficit.

- Using a steel frame is equivalent to pumping an extra two years' worth of average household CO2 emmisions into the environment.

Steel And Timber Framing: The Afterlife

Steel And Timber Framing: The Afterlife

- Timber building components can be used in other buildings or buried in a landfill at the end of their useful life. In a landfill, up to 97% of the carbon in the wood is permenantly stored offsetting CO2 released by fossil fuels.

- At the end of a building's life, the steel in steel frames can be recycled for other use. This requires significant processing energy, emitting more CO2 into the atmosphere.

Information sourced from and presented courtesy of NZ Wood - See www.NZWood.co.nz.